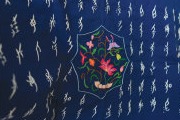

Fabric from antiquity

For example, starching the thread takes a lot of work.

"You need to prepare the starch (made from rice and oil) just about right," says Tang.

If it's too thin, it won't be strong enough to keep the thread from splitting, but if it's too dry, it makes it difficult to wrap the thread into the shuttle.

Moreover, it takes work to make sure every bit of the thread is fully immersed.

"The ultimate goal is to make it smooth, easy to weave," says Tang.

An experienced worker like Tang, who typically works 10-12 hours a day when she is not busy doing farm work, can weave around 10 meters of cloth in a day.

But she is currently the manager at the plant, where there are roughly 400 employees who mostly work flexible hours.

"They do farming in the daytime during the harvest season and weaving at night," says Tang.

Tang's plant can produce 38,000 pieces of grass linen a year.

And currently, a piece of cloth that is 23 meters long and 0.36 meters wide sells for around 800 yuan ($117.1).

As of now, there are six companies making grass linen in Zhouxing, creating jobs for 1,000 locals, according to Luo Xingyu, an official with the Zhouxing government.

Each of them earns around 8,000 yuan a year on average.

Grass linen from Zhouxing is mainly exported to South Korea and Japan, with 300 million yuan in annual sales, Luo says.

In 2017, Longchang exported $20.7 million worth of grass linen, the local economic and information bureau says, with Zhouxing accounting for 67 percent of the total.

Meanwhile, the Longchang government has ensured large-scale ramie plantation over the years to ensure raw materials for grass linen production. And it also encourages grass linen masters to take in apprentices to ensure that the craft survives.

So far, more than 3,000 locals in Zhouxing have got grass linen making down to a fine art, which has helped them to get out of poverty.

"Even children and the elderly can earn by wrapping the thread into the shuttle," says Tang.