Farmer tunes into success as master violin craftsman

SHIJIAZHUANG - Thomas Bohme, lead engineer and project manager of the German musical instrument manufacturer GEWA, has the final say on the quality of exported violins made by a Chinese company.

For Bohme, the word Huang is synonymous with perfection.

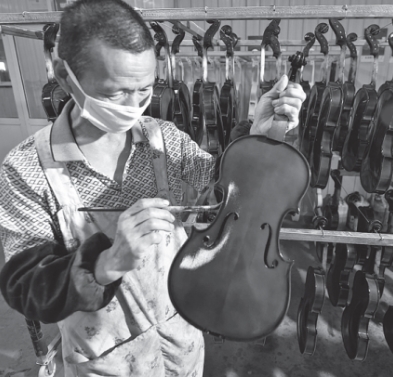

It is the surname of Huang Guoquan, a 50-year-old violin painter at the Wuqiang Jiahua Musical Instrument Co, in North China's Hebei province.

The Germany-headquartered GEWA is one of the largest musical instrument manufacturers in Europe, and Jiahua serves as its major violin producer in China.

Huang used to do farm work in Huangtun village of Wuqiang county and learned violin varnishing and shaping techniques from scratch. He has trained himself to become a master craftsman in the field in the three years since he joined the company in 2016.

He has nurtured a dozen apprentices and has been dubbed the "grassroots master" by his fellow luthiers at the workshop.

Ten years ago, the birth of twin boys and a college-age daughter to support laid a heavy burden on Huang and his wife, compounded by an injury to Huang's left arm.

"Back then, I wasn't able to do manual labor for a long time," Huang recalls."With no source of income, the family was plunged into poverty."

As late as 2016, Huang's family was living on a few acres of land.

"We wore old clothes that others threw out, and we barely had meat for meals," Huang says. The ex-farmer who knew nothing about music never dreamt that he would one day make a connection with violins and guitars.

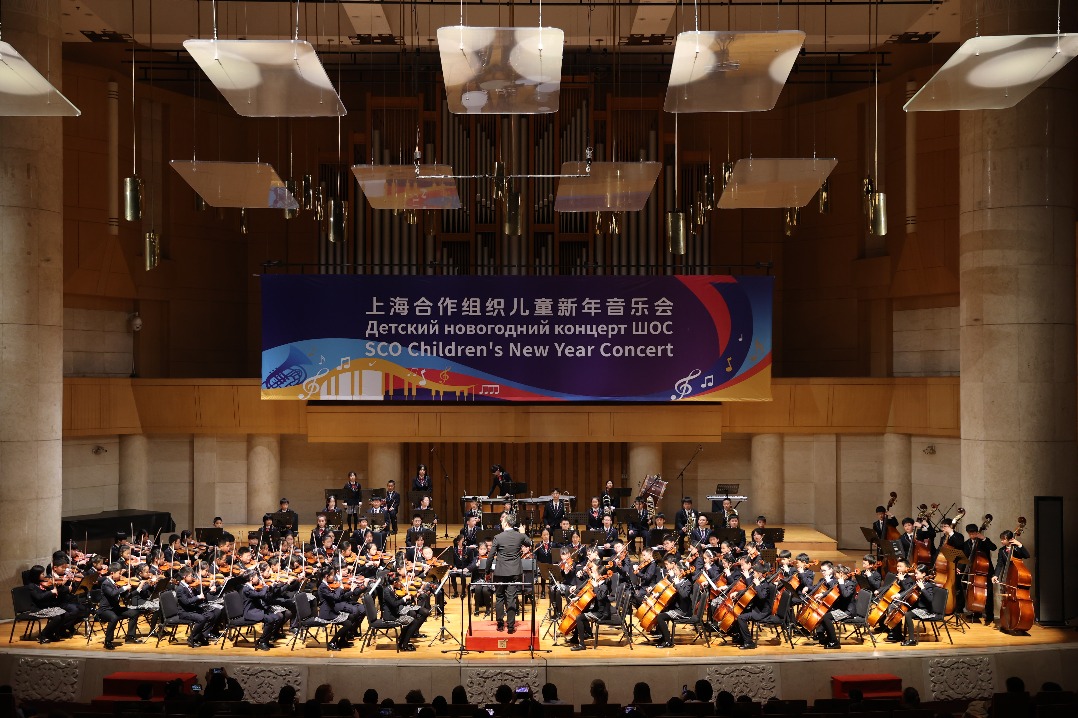

Wuqiang's musical instrument manufacturing industry started in the late 1980s. More than 70 manufacturers now employ 10,000 people. The county's production of Western wind instruments ranks first in China and second in the world, selling well in over 80 countries and regions.

It was why Jiahua Musical Instrument moved from the neighboring Tianjin to Wuqiang and started production at its new location in 2014, according to Yan Bin, the general manager.

The company decided to recruit workers from poor households in Wuqiang to tackle unemployment and support the county's poverty-relief efforts, Yan says.

Huang signed up without hesitation when he heard the company was hiring. His first encounter with Bohme was when the German expert was explaining violin-making skills and procedures to the newly-hired locals in Jiahua's workshop.

The hard-working and studious man often pays great attention to details and has gradually refined his skills. Through trial, error and dedication, Huang can now paint as many as 50 violins a day compared with the early days of his career when it was just a few.

In one product inspection last year, Bohme rested his eyes on a finished violin as fine and exquisite as those varnished by European master luthiers. He got some other violins made by Huang and found every one of them superbly made, almost perfect technically and artistically.

As Huang becomes well versed in violin-making, his monthly salary has increased from some 2,000 yuan ($287) to 5,000 yuan. The family is better off and will not fall back into poverty, he says.

"I have a wish that one day my hard work can create favorable conditions for my twins to learn an instrument," says the father."It would be best if they can play the violins I make."