Instruments of change

Now, however, many of the manufacturers of the instrument can play it as well, as it's important to know how to tune it, he notes, adding that the production method has also become standardized. Couriers are more frequently seen, now, as well, he explains, due to the increase in e-commerce sales, adding that there are also professional training institutions for children and adults.

Xu Yongshun, director of Xuchang village, told media that back in 2014, Xuchang was a poor village, and only two or three families made musical instruments. The village reduced poverty by developing the industry and, now, products from the village are sold across the globe, with an annual output value of 120 million yuan.

"Per capita income reached 50,000 yuan annually. Let's say we have set a foot on the path to moderate prosperity," he told Henan TV.

Once a poor county suffering from sandstorms, floods and unproductive saline soil, Lankao, empowered by the spirit of survival, is now one of the three major folk musical instrument production centers in China, alongside Dunhuang, Gansu province, and Yangzhou, Jiangsu province.

The county, with about 6 million paulownia trees, produces more than 90 percent of the country's paulownia wood soundboards. Its 268 factories produce around 700,000 musical instruments and 5 million related accessories per year. Occupying about 30 percent of China's folk musical instrument market, its products are sold to over 10 countries and regions and annual production value in the county has reached 2 billion yuan.

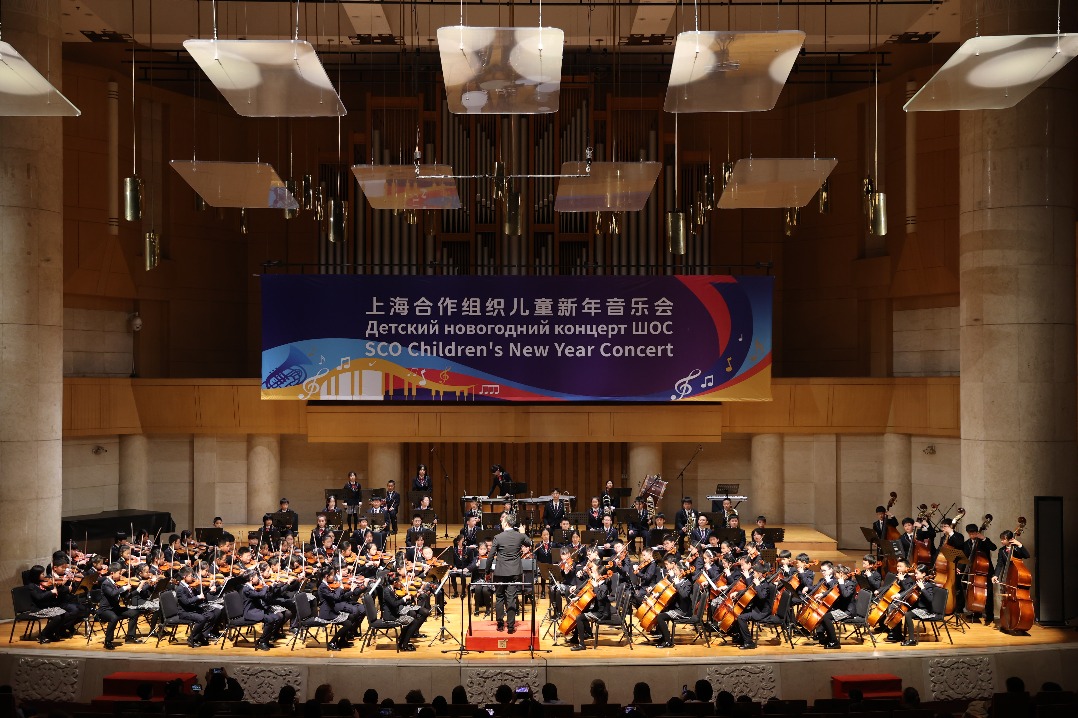

Xu Yachong says his future dream is to help make guqin a landmark of Lankao, and develop the business into a large-scale industry. He also plans to open a training institution, "so that more people can learn and appreciate the art".