Engineer builds a new life

It took him more than a year to finally make it, but he was not satisfied and, in January 2020, he tried to optimize it.

"I tried a gyroscope sensor with a larger rotor and higher rotating speed to make the self-driving function more stable, but I made a mistake and the explosion occurred," Liang recalls.

"When I regained consciousness after several seconds, I found myself lying on the ground and then I realized my leg was gone.

"I was quite calm and even recorded a video, and kept apologizing to my wife and son and said goodbye to the world," he adds.

When Liang underwent his amputation, his wife was giving birth to their second son in the same hospital.

After being in hospital for more than 20 days, he returned home and was ready for the real test-life without his left leg.

"Physical recovery is the first step. Psychological acceptance matters more, which takes much longer," Liang says.

Closing his company, he set aside one year to accept his new body.

"It is my wife and my two sons, who keep motivating me. I must persist and giving up is not an option," Liang says.

Every night at about 2 or 3 am, phantom limb pains disturb his sleep.

Thirty-six days after losing his leg, Liang, literally, got back in the saddle, not to drive, but to feel the roaring engine once again in hope that normality would, one day, return.

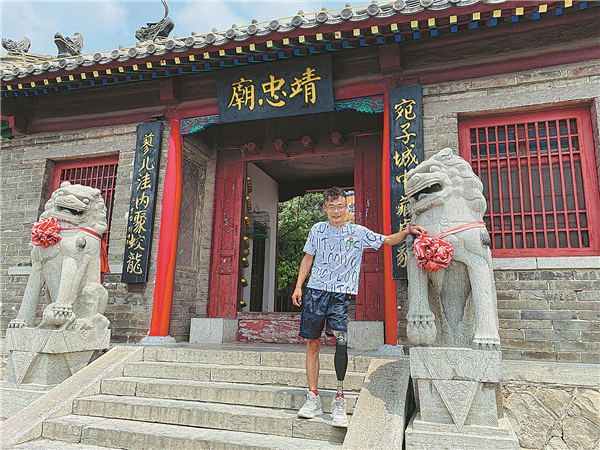

About two months after the accident, he got his prosthetic leg and, on the 100th day, he could walk without crutches.

Finding hope

On short-video platforms, Liang saw other people with physical challenges who live no differently from other people. They ride bicycles, dance and even ski, using their prosthetic limbs.

"Inspired by them, I started to post videos about my daily life," Liang says.

He adds that short-video platforms help people with similar situations find one another and communicate.

"Although I don't know who they are, or what they have been through, their supportive, kind and encouraging words have lifted me up," he says.

Liang's focus is now on making the new leg comfortable.

"I have experienced some inconveniences and awkward moments while using the prosthetic leg, which has made me think about how to modify it," Liang says.

Security checks when traveling, especially at airports, can be a bit problematic.

"Although invited to a private room for further screening, I still feel quite awkward taking off my trousers in front of several guards," Liang says.

To avoid such incidents, he spent several days in early May upgrading his prosthesis.

Through design, modeling and manufacturing, he made a coupling device to connect the socket of the leg with the prosthetic knee.

"With the gadget, people like me can take the leg off in one second without having to remove a screw," Liang explains.

"The security check while traveling is just one scenario; others include trying on clothes in fitting rooms, shoes at shopping malls, and changing from 'feet' to a running blade before jogging."

To know about the structure and system of the prosthetics better, he disassembled some secondhand prosthetic limbs that were made in China and abroad, which cost him hundreds of thousands of yuan.

"I want to let more people know about these high-tech prosthetics, which are comfortable and safer to wear. It can boost confidence with every step," Liang says.

"The only thing is that the cost is unaffordable for most families, usually ranging from 200,000 yuan ($29,900) to 800,000 yuan," he says.

Liang adds that due to the small market, there are few companies in China investing in the research and development of such prosthetics.

To advance functional performance and help amputees maintain or regain their freedom of movement, Liang has provided his experience and suggestions to several prosthetics companies.

"If there is a good opportunity, I want to make high-tech prosthetics accessible and affordable to more amputees in China," Liang says.